The first time I encountered a specialized fish filleting tool was during a rush period at a popular seafood restaurant. I observed a professional chef perform fish disassembly with both precision and careful movements and it captured my attention completely. I experienced my first fish filleting tool during that morning shift which led to my long-term study of these unique instruments. My objective is to share this exploration that starts from the origins of these tools and continues through their present-day variations as well as selection recommendations for professional settings. The extensive journey of personal learning and hands-on training has brought me valuable insights which I aim to share with others who work with culinary cutting tools.

Section 1: The History of Advanced Fish Filleting Tools

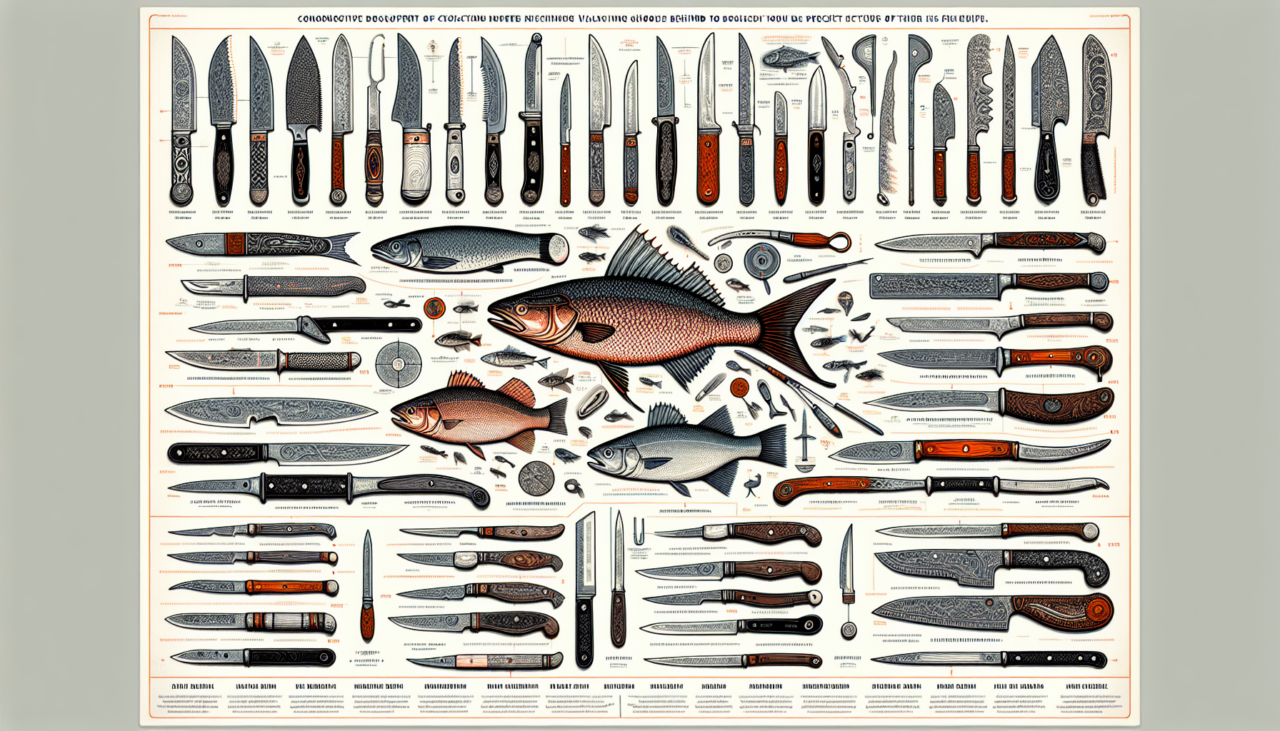

Specialized fish filleting equipment has evolved through ancient coastal civilizations in a way that matches its importance for modern seafood preparation. People who lived near coastal areas and relied on daily fish captures learned to create their own tools by using available resources. People used stone, bone and wood to create basic cutting tools which later evolved into advanced cutting instruments through the process of cultural exchange of ideas and techniques. A historical study of these tools reveals how intuition and craftsmanship combined to create the modern precision instruments we use today. The extensive historical development of fish filleting equipment influences how professional chefs view the combination of engineering with artistic elements in their tools.

Subsection 1.1: Early Innovations in Fish Filleting Tools

Remote fishing villages experienced necessity as their driving force for innovation. Fishermen from ancient times adapted their surrounding resources to make effective cutting tools. The first filleting tools featured curved sharpened edges which delivered optimal results for fish filleting while maintaining the fish’s tender flesh. The artisans carefully sculpted comfortable-handling shapes which withstood harsh saltwater conditions. The following key characteristics emerged during the development of early innovations:

- Fishers used natural materials such as bone, shell and flint

- The ergonomic design emerged from manual woodworking and horn carving techniques

- The instruments functioned as two-in-one tools for filleting and de-boning seafood

These functional designs fulfilled the survival requirements of fishing communities before advancing into technological developments.

Subsection 1.2: Modern Breakthroughs in Design

During the industrial era technological progress together with new materials transformed these filing instruments. Modern fishing tools consist of high-grade stainless steel combined with engineered polymers which provide better durability and precision along with resistance to corrosion. The current production techniques use machine guidance in blade forging which produces instruments that achieve both perfect balance and comfortable design. Through decades of design progress professionals now possess instruments which combine both attractiveness and superior functionality. The transformation from hand-carved basic shapes to modern high-tech molded instruments shows how innovation and traditional values unite in all kitchen instruments used today.

Section 2: Exploring the Range: Types of Professional Fish Filleting Equipment

The current market showcases a wide range of specialized fish cutting tools that have evolved from their historical beginnings. These instruments exist in multiple designs that serve different purposes whether used in culinary establishments or seafood processing facilities. Professionals know that one tool does not serve every requirement because different models specialize in precise filleting or heavy-duty industrial operations. The selection process between available models stands as important as mastering the cutting technique according to my practical knowledge. Safety and operational efficiency during extended work shifts are guaranteed by careful equipment choices found in the market.

Subsection 2.1: Distinct Features Across Models

A thorough inspection shows that small distinctions between instruments significantly affect the performance during daily activities. Manufacturers now prioritize developing tools which combine reduced wrist strain with peak blade performance and extended tool life. Blades used in high-quality tools are engineered to stay sharp throughout continuous usage while providing effortless cleaning after intense operations. The handles are made of non-slip materials which stay comfortable during both quick movements and repetitive actions. The comparison points among professionals focus on three aspects:

- The blade material must fight against stains and corrosion

- The ergonomic handle structure provides a dependable grip function

- The total weight distribution of the instrument leads to improved accuracy together with simple operation

The careful examination of these details gives the experienced user a competitive advantage in fast-paced kitchen settings.

Subsection 2.2: Comparing Old and New Instruments

The advancement of cutting tools between past innovations and modern craftsmanship demonstrates an exceptional transformation. The current tools differ from their earlier counterparts because they result from state-of-the-art engineering and material science advancements. The design evolution moved from cumbersome functional tools to lightweight ergonomic instruments which decrease operator fatigue in prolonged operations. Professional users provide feedback to manufacturers who use this information to develop improved products that fulfill strict industry standards for blade, handle and balance components. The available choices come in various types that meet particular processing requirements so you can find the one which suits your workspace needs exactly.

Section 3: Selecting Your Tool: How to Choose the Best Fish Filleting Equipment for Professionals

The appropriate instrument leads to enhanced operational productivity while producing superior end results. Thoughtful evaluation becomes necessary to select from the wide range of advanced market options. Professional kitchens together with processing facilities require the selection of tools based on their operational needs and worker comfort as well as specific cutting requirements. My experience has shown that optimal decisions emerge from combining expert guidance with practical testing along with precise departmental needs assessment. Professionals obtain the chance to analyze design performance at this stage.

Subsection 3.1: Key Factors in Your Decision

Several factors play into picking the perfect instrument for delicate jobs and high-volume operations. The blade quality must possess both precise cutting ability and sufficient durability for sustained usage in heavy conditions. A handle should have both natural grip comfort and specific features that stop slips under wet circumstances. A tool requires proper weight distribution because an unbalanced design will cause fatigue which slows down processing times. When evaluating suppliers or testing instruments practically focus on:

- Blade sharpness and material quality

- Handle ergonomics and non-slip design

- Overall balance and ease of maintenance

When you place these features at the forefront you create conditions for smoother operations which reduce service interruptions during peak periods.

Subsection 3.2: Expert Tips for Professionals

Through time I have learned that actual usage remains the best method. Many experts agree that testing tools under practical working situations reveals essential performance aspects which standard specifications fail to display. Begin by scheduling a demonstration while asking for trial instruments for evaluation during a specified time period. Engage with peers and ask for recommendations based on their experiences in busy, real-world settings. My essential piece of advice to others involves examining professional reviews and comparing their feedback. The practical method stands as a valuable tool for selecting new equipment in your market search. The guide delivers straightforward guidance to select appropriate tools for specific functions which will enhance both operational speed and product quality.

When choosing the right fish filleting instrument, a person has to understand traditional craftsmanship, explore various modern innovations, and pick the tool that will fit the person’s workflow. Make sure to try instruments yourself, consider the details of the design and get recommendations from your colleagues who have experience. It is always worthwhile to make your decision with intent, especially when it comes to upgrading an aging tool or starting with a new line of equipment. Take these insights to heart—invest in quality, and your daily performance will speak volumes about your commitment to excellence.

By Liam Poster